- Home

- About Us

- Products

- Brands

- AEG

- Apex

- Bosch

- Chicago Pneumatic

- Carborundum

- Eibenstock

- Eisenblatter

- Fischer

- Hitachi

- I.T/Addison

- Jug

- KPT

- Makita

- Makita Garden Tools

- Maktec

- Milwaukee

- Mitutoyo

- Miranda

- Powermaster

- Ralli Wolf

- Sunner India

- SKF

- Taparia

- T.I Diamond

- Totem

- Taco

- Services

- Contact Us

Carborundum> Honing & Finishing |

|

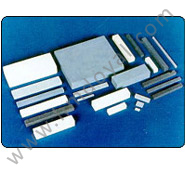

Honing is the finishing of internal dimensions of automobile cylinder heads and other components when an excellent and accurate finish is required. Super finishing is the production of very high finishes, as high as 0.02 um, on the outside diameters of components and inside diameters of bearing rings, bearing races and all other components where friction is to be reduced to the barest minimum. Honing and Super finishing are generally performed with squire, rectangular or specially shaped sticks or blocks. Honing stones can be used for all forms of honing, vertical, horizantal and flexible or oscillating. |

||

|

Ion honing, the abrasive stones are held in the Honing head in sets of 4, 6 or 8 pieces. The Honing Process comprises longitudinal and rotary motions of the honing head to generate a cross hatch pattern. This pattern is necessary to provide lubrication by retention of cutting fluid. The cutting fluids normally used are straight cutting off, kerosene and mineral seal oil. Super finishing is generally done in stages of 2, 3 or 4. Roughing is done with White Aluminium Oxide stones of grit sizes 400, 600 and 800. The finishing is done with Silicon Carbide stones of grit sizes 800, 1000 and 1200. |

||

© Copyright 2013, all rights reserved with H. M. Doyal & Co.

|

|